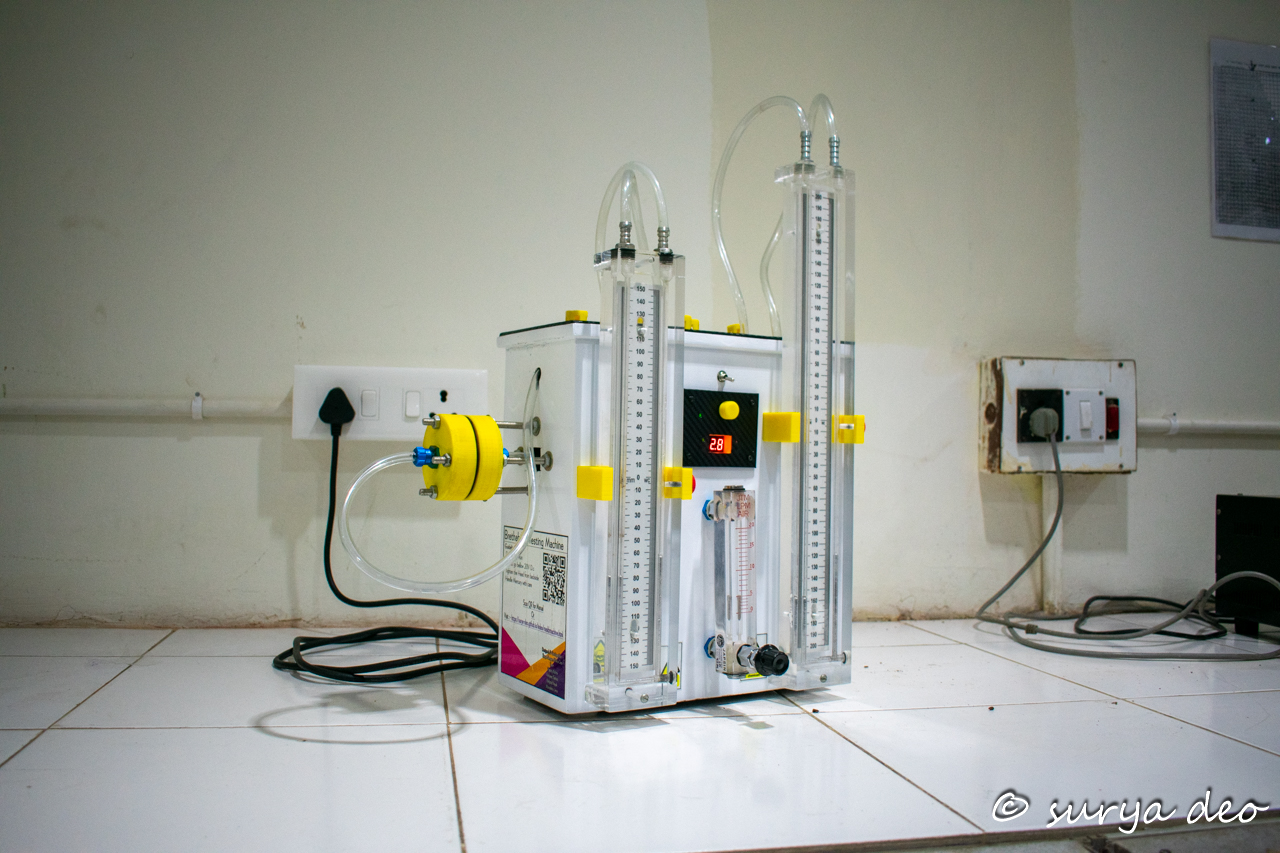

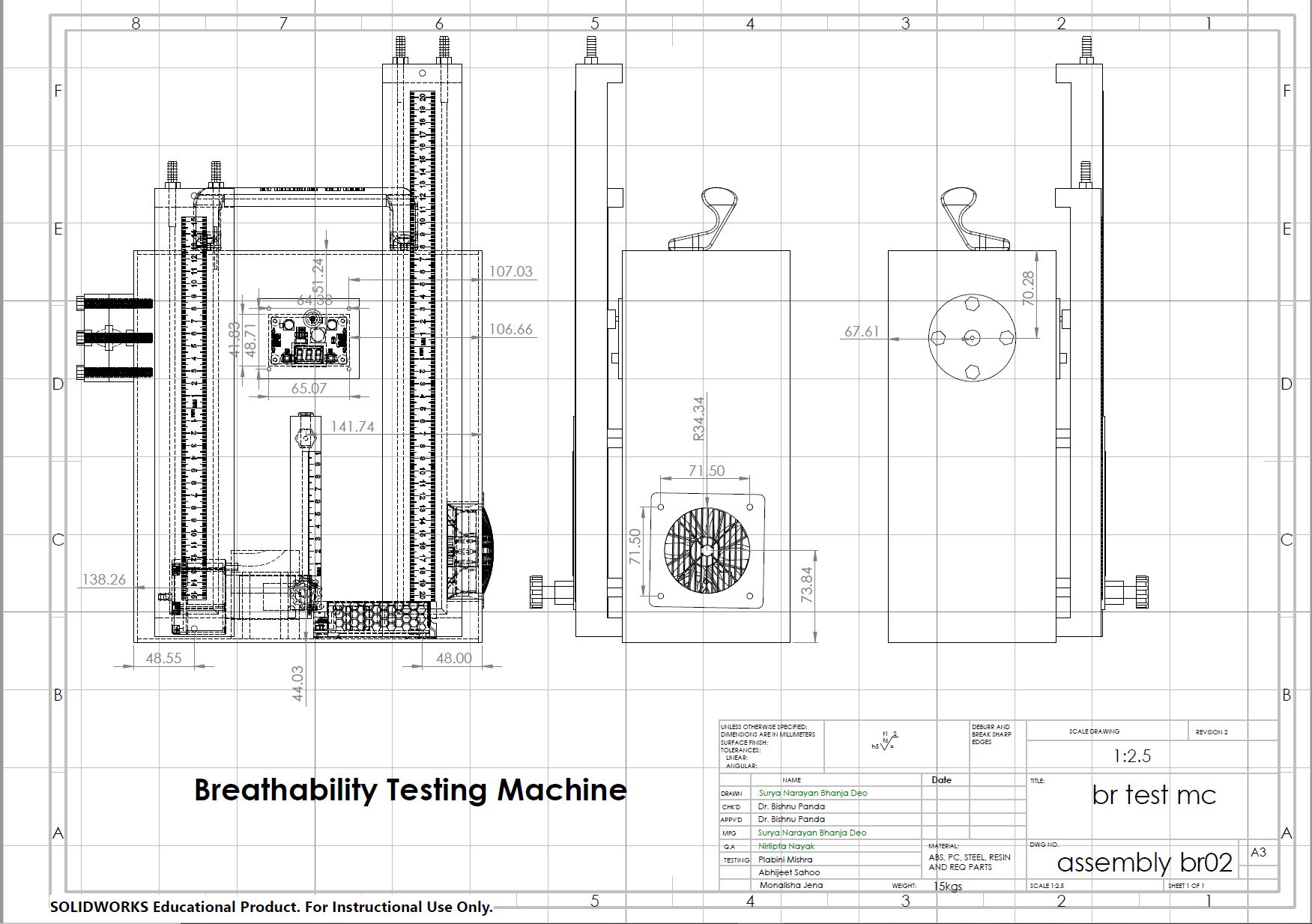

Brethability Testing Machine, is a device that measures pressure differential required to draw air through a measured surface area at a considered air flow rate is used to measure the air exchange pressure of the mask material as shown in the figure.

Mask has become a inseparable part of our life. It is after the Covid-19 pandemic we are slowly understanding the actual importance of mask. Masks are not just to reduce chance of getting a viral dose but they too protect us from common cold viruses and provide a filtering agent for us to protect us from a polluted external environment It is a good practice to wear a mask in labs industrial areas to protect our health and improve our life spans. Simply speaking, Masks are are necessity.

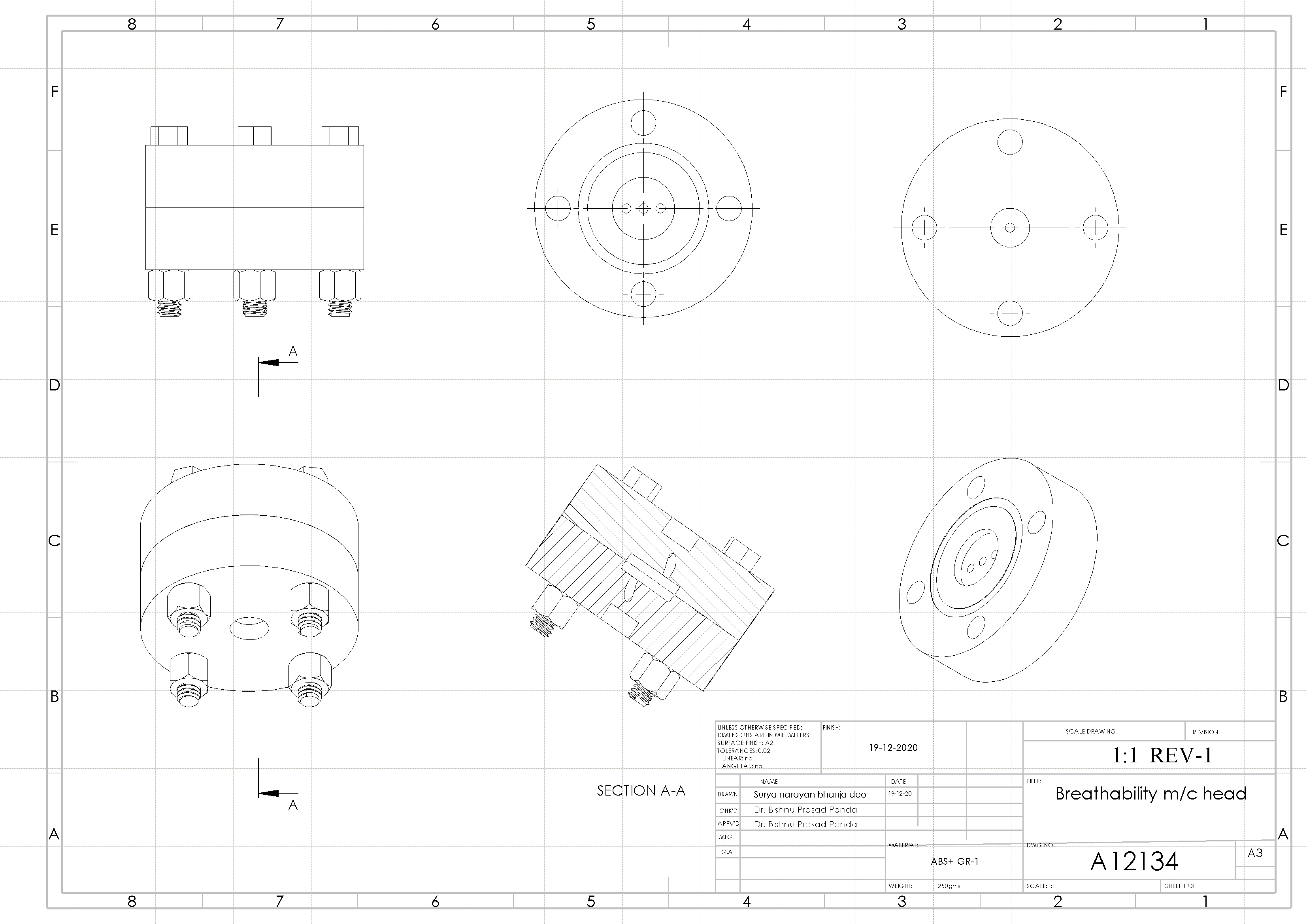

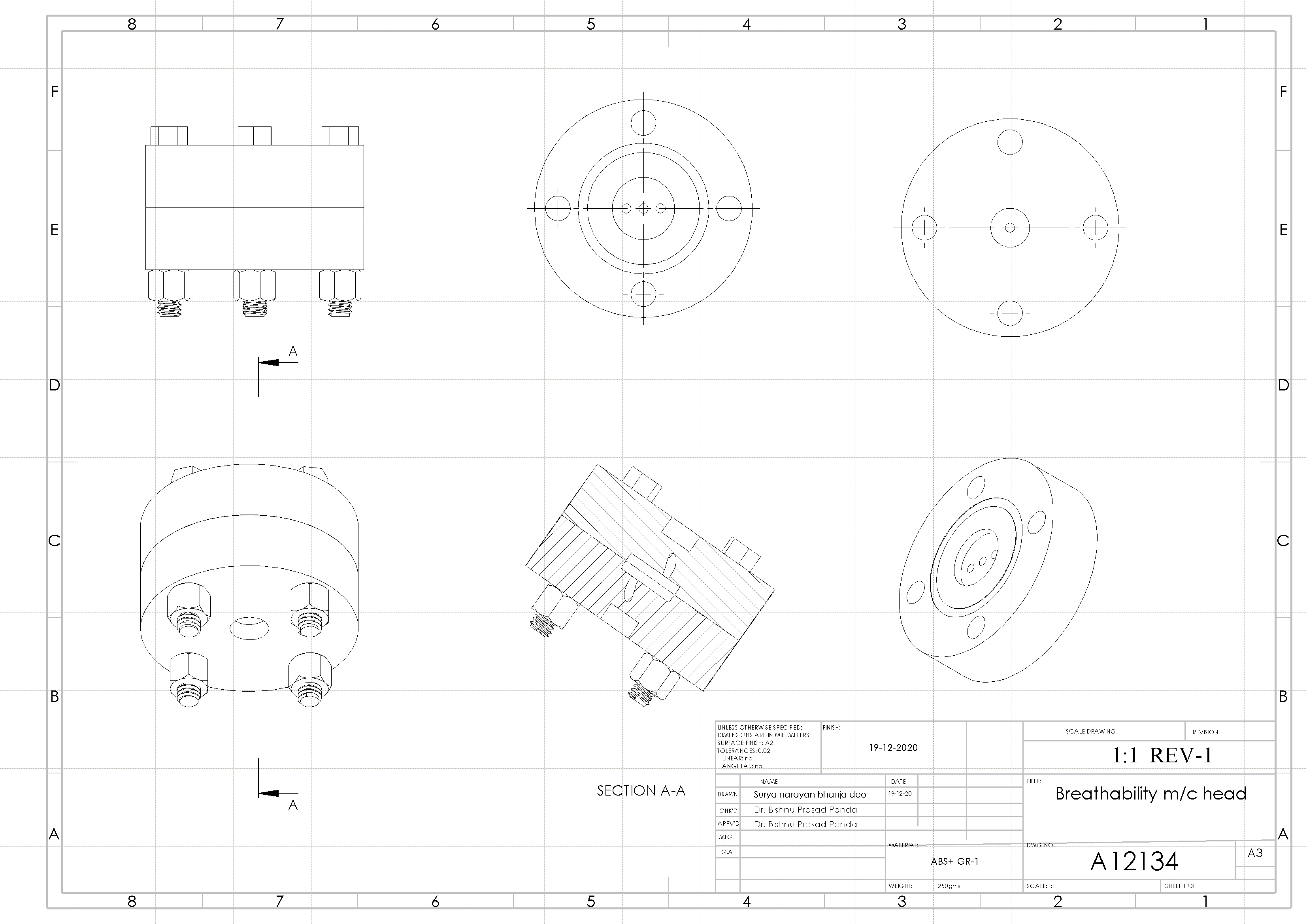

Specially Designed Head

100 WATTS

Mercury Filled

Robust construction

Voltage Regulated

Fine tuning of Flowrate LPM

Surgical Masks, N95, Cotton Masks etc

A device which measures the pressure differential required to draw air through a measured surface area at a constant air flow rate is used to measure that the air exchange pressure of the surgical mask material, as shown in Fig.7. Mercury –Filled manometers(M1 and M2) are used to measure the pressure differential. A flow meter is used for measurement of the air flow. An electric vacuum pump draws air through the apparatus and a needle valve is used to adjust the air flow rate. Standards, calculated cross-sections for sampling are also very important.

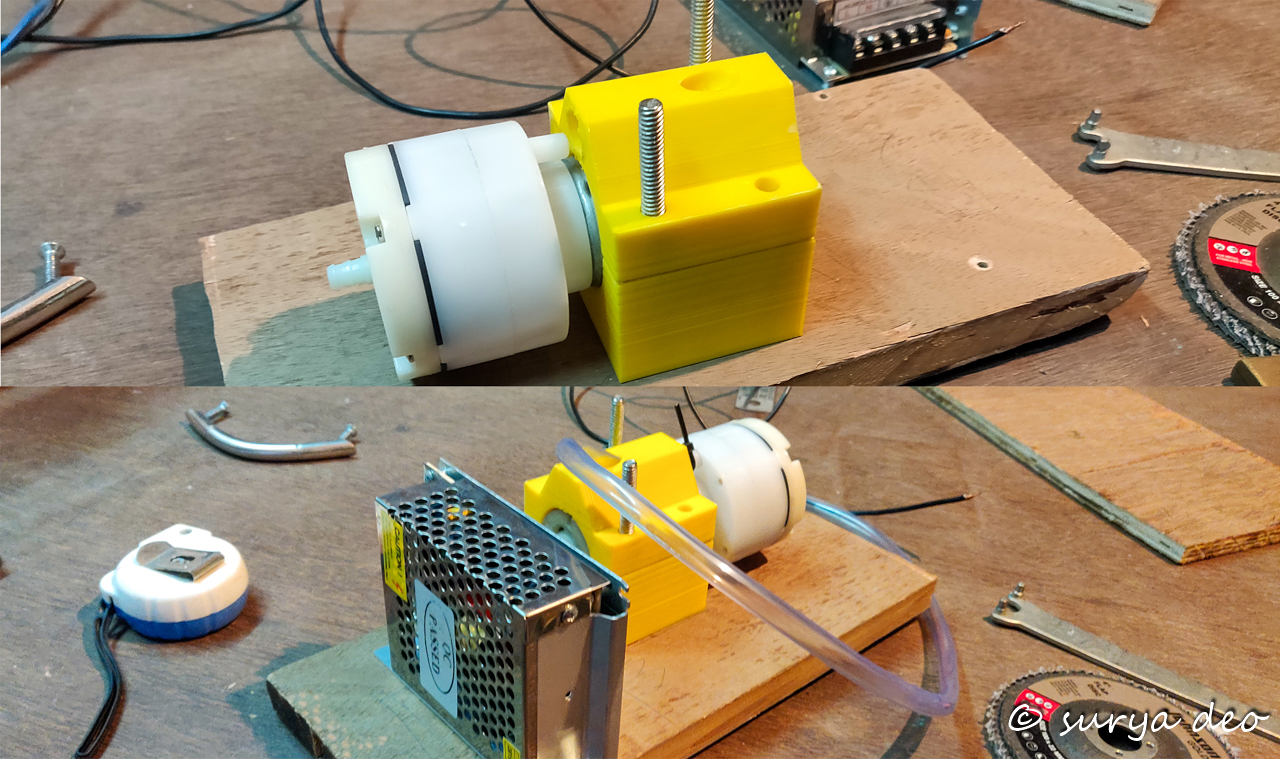

Specific mechanisms and their parts were manufactured using Fused Deposition Modeling.

For protection against current covid-19, masks are currently very important part of our lives. People are now wearing many different types of masks, including hand-sewn masks, and disposable medical masks. Currently, different type of masks are available in the market and with the increased no of manufacture and most of the manufacturers are not maintaining the required set quality criteria as per the guidelines issued by WHO and no quality parameters are being maintained. In many cases, mask choice depends on the availability and people uses what they have. To be effective, a mask needs to both filter out particles and allow a person to breathe easily. The ease of breathing through a respirator, surgical mask, or cloth mask is typically measured by the pressure differential between the two sides of a mask as air flows through it at a rate similar to that during breathing. For a mask that is asymmetric or made of heterogeneous layers, the air pressure differential could be directionally-dependent air pressure. The pressure differential across a fabric or mask under a given face velocity is an indicator of how much the material impedes air flow. This is directly related to the breathability of a section of material: higher values of pressure differential indicate that the fabric or mask is harder to breathe through and lower values mean that it is more breathable.

We designed developed and manufactured the machines in house which gave us experience and insights into these machines and their manufacturing challenges. I extend special thanks to Dr. Bishnu Prasad Panda Sir for his support and Guidance and to my team for constant support.

The equipment is developed in line with Indian standard IS 16289:2014 and also presently

calibrated by certified NABL laboratories.

The equipment is placed at Testing department, CIPET Bhubaneswar and evaluation

studies are being carried out to study other suitable areas and viability.

The equipment has also tested with different market available masks and results are found

can be correlated with the other laboratory results.

CIPET, Bhubaneswar also earlier developed an indigenous equipment for Blood penetration

resistant tester for testing and certification of coverall and being certified by National

Accreditation Board for Testing and Calibration Laboratories. Govt. of India and Bureau of

Indian Standard, Govt. of India.

The developed equipment is low cost equipment and can be fabricated easily and the

equipment can be used for certification of market available masks at very low cost.

The equipment can be supplied to many NGO and other Govt. bodies fabricating at low cost

which can be used for quality evaluation of masks being manufactured.

This can support to Atmanirvar Abhiyann of India. All the parts being used can be

indigenously fabricated.

Currently, similar equipment available in the market are very high cost and price varies

between 2-5 lakhs and many are imported from other countries.

SURYA NARAYAN BHANJA DEO (CONCEPT DEVELOPMENT, PRODUCT DESIGN, DEVELOPMENT & FABRICATION)

ABHIJEET SAHOO (FEASIBILITY STUDY)

PLABINI MISHRA & MONALISA JENA (TESTING, STANDARDISATION, & NIRLIPTA NAYAK QC REPORT GENERATION)

GUIDED BY- Dr. BISHNU PRASAD PANDA, HOD (ME)